Worktops for outdoor kitchens require a millimeter-precise fit. Depending on the module, special requirements apply when cutting to size. Each module has an individual width - depending on its position and the adjacent elements. For example, gaps or overhangs need to be taken into account. The cut-outs for devices and connections must also fit exactly.

In the past, every outdoor kitchen was cut to size manually - a considerable effort with a high risk of error. Today, the configurator takes over this step completely. Dimensional drawings are created at the touch of a button and sent directly to production.

- Combeenation

- Why

- Case Studies

- BBQ Kitchen in detail

THE COMPANY

BBQ Kitchen's passion for Weber barbecues gave rise to the idea of developing a high-quality outdoor kitchen - perfectly compatible with the market leader's popular barbecue series. The clever add-on system enables seamless integration for an incomparable outdoor barbecue experience.

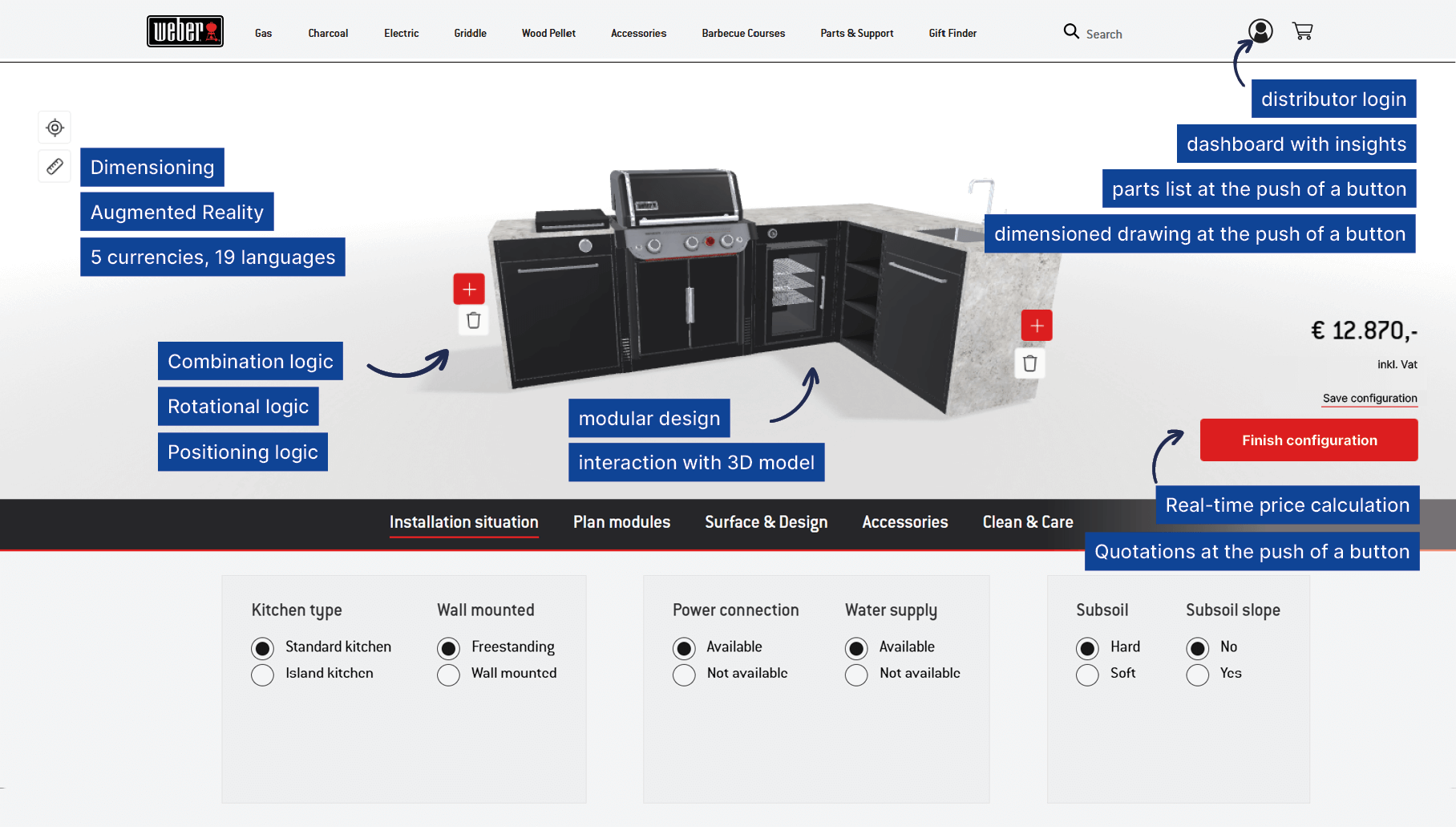

The CPQ solution

1. Configurator

- Error-free configurations – the configurator ensures that every selection made is valid and producible.

- No queries – a standardized information base ensures that all users, especially dealers, can act safely and independently.

- Enormous range of variants and combinations - yet always technically correct configurations.

- Automatic parts list creation – all individual parts of the configuration are automatically recognized and saved during runtime.

HIGHLIGHTS

2. Price management

- Pricing at the touch of a button – no waiting times, no vague guidelines. Instead: precise prices in seconds.

- Error-free calculation – exact price calculation guaranteed without calculation errors.

HIGHLIGHTS

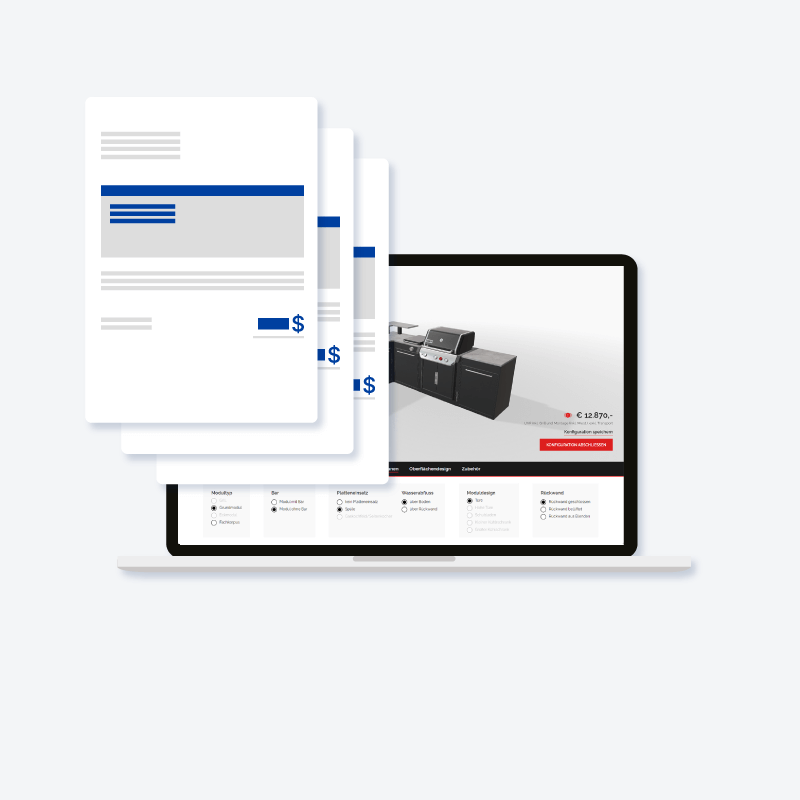

3. Quotation management

- Fast response time - quotes are now created in just a few minutes, no longer in several days.

- Error-free quotes – Manual input errors are a thing of the past.

- No feedback loops – Everyone involved, from sales and dealers to customers and production, has access to the same level of information.

HIGHLIGHTS

Offers that fit right away.

In the past, users had to know exactly which module can be combined with which sink, which grill fits next to which built-in element or whether the worktop extends over one or two modules. Sounds complicated? With over 1 billion variants, it was.

The complexity was enormous, errors were inevitable and the cost was correspondingly high. Today, the process runs smoothly, quickly and error-free. A real relief for everyone involved.

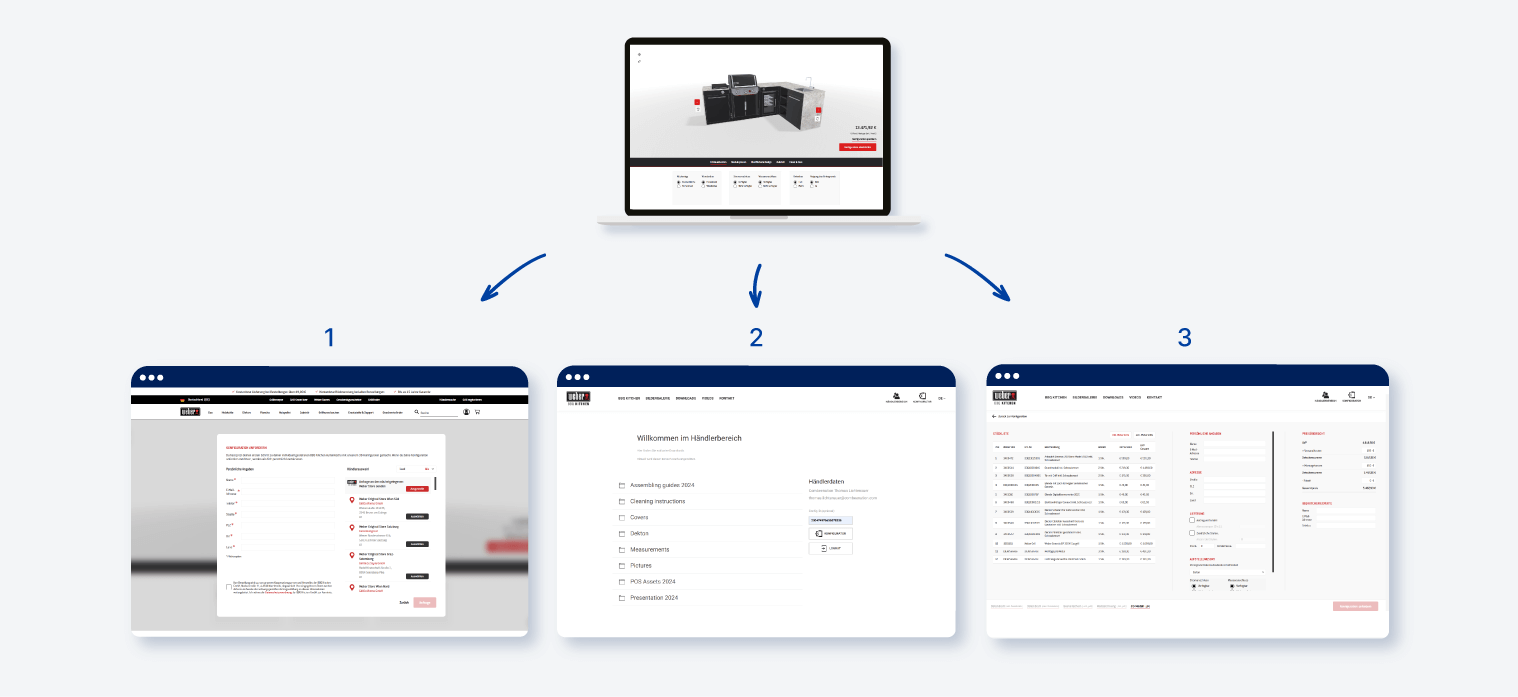

Offer process in detail

- An anonymous user puts together their BBQ Kitchen on weber.com, then clicks on “Request configuration” and selects the nearest dealer (see image 1).

- The selected distributor receives the configuration ID by email and can easily access it in the BBQ Kitchen portal (see image 2).

3. In the distributor view (see image 3), additional options are available to the registered dealer. These include a detailed parts list, the option to calculate prices, download the dimensional drawing and the option to generate a data sheet - and much more.

Practical excursion

Worktops are cut to the millimeter and flawlessly.

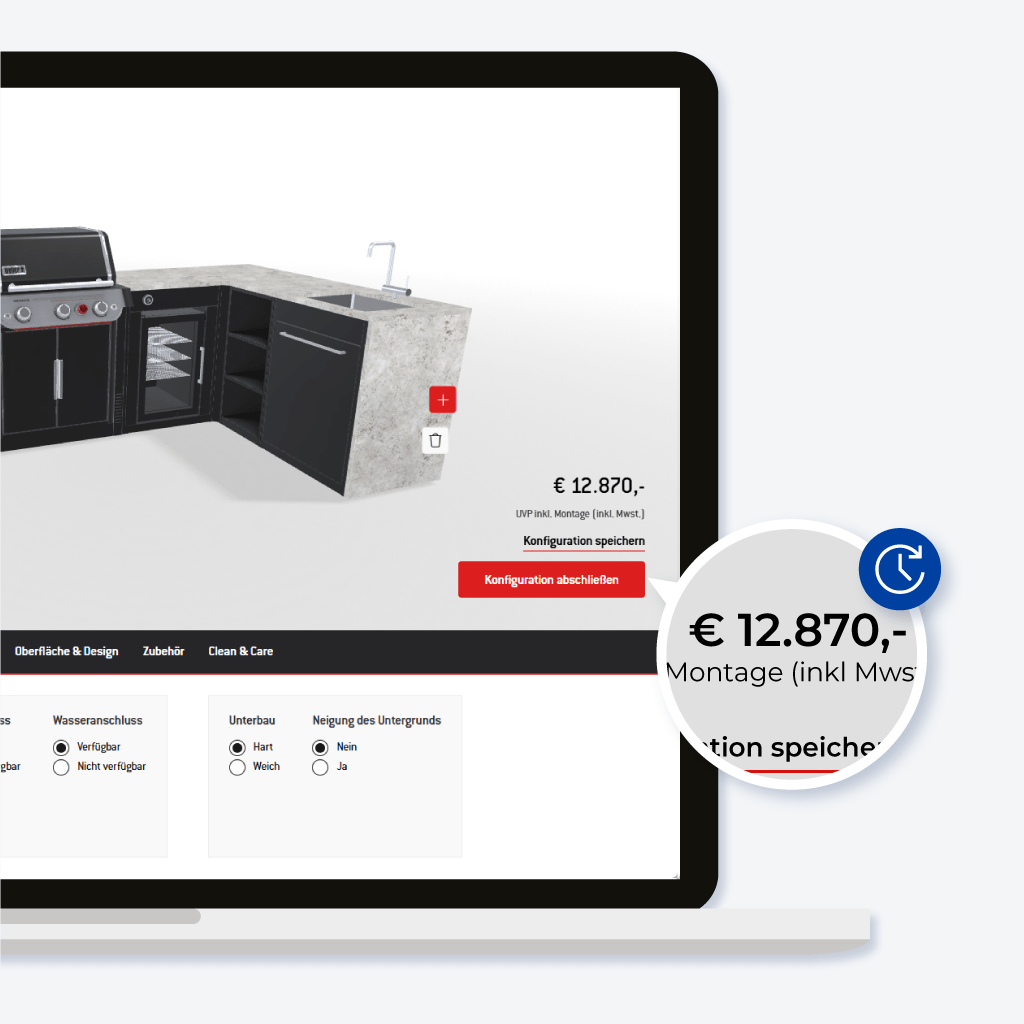

From target price to real-time calculation. No matter how often things change.

In the past, the initial price estimate was often based on a rough guide value - a far cry from an exact quote. For an exact calculation, all modules then had to be calculated manually. This included numerous factors such as handles, worktops, positions and sizes. An extremely complex and time-consuming process.

Today, on the other hand, quotations and price estimates can be created in just a few minutes. Even last-minute customer changes no longer require a complete recalculation - this saves time and reduces errors.

Own distributor surface

In the outdoor kitchen configurator, retailers benefit from extended functions: In a dedicated interface, they can call up and customize configurations, set individual discounts and shipping costs and generate parts lists, data sheets and precise dimensional drawings with just a few clicks.

Easy to maintain parts list

The parts list contains over 200 individual parts that are relevant for the configuration. Don't worry - BBQ doesn't have to maintain every conceivable product combination, just the individual components. For each configuration, the appropriate parts are automatically selected and added to the parts list.

All-round carefree package

Does a CPQ project sound complicated? Not with us. We took on the entire project for BBQ - from the product logic to the price and discount structure to the streamlined quotation process. Even complex details in the background? Everything with us. This allowed the BBQ team to concentrate fully on its core business.

A decisive advantage in this project: BBQ was able to provide us with STP files of the modules. These were already modeled in 3D and dimensioned to the millimetre - the perfect basis. We prepared and converted the files for the web application so that they could be used seamlessly in the configurator.

Speed up your quotation process.

Let us advise you without obligation - we will be happy to make you a personalized offer.

REQUEST NOW